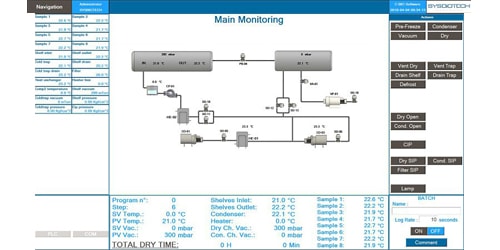

C-BIO2 SCADA system

C-BIO2 SCADA system controller was developed as a fully custom-made solution with considerable cost and short learning time. Flexibility and stability are key features of our standard system based on powerful PLC. SYSBIOTECH equipment operates under State-of-the-Art SCADA system.

C-BIO2 can manage most of biotechnological equipment which is commonly used in lab-, pilot- and production-scale processes:- Fermenters

- Bioreactors

- CIP-systems

- Process tanks

- Filtration skids

- Separation skids

- Freeze-dryers

With SYSBIOTECH SCADA C-BIO2 you can arrange wide range of configuration and connections between equipment, for example:

media preparation vessel –> seed bioreactor –> main bioreactor –> downstream equipment –> CIP-system

With our standard SCADA you can get your customized solution.

The unique feature of SYSBIOTECH controller system is fully scalable platform from lab- to pilot- and production scale fermenters and bioreactors. In the smallest bioreactor (total volume is 250mL) you will get the same functionality and logic as in the largest one (total volume is 35 000 L).

When the computer is turned on, the C-BIO2 software can be launched by the shortcut on the desktop, so the main window displays once completely loaded. The main window shows a graphical representation of the fermentor/bioreactor and the current control situation.

- Universal control system for all SYSBIOTECH range of equipment.

- You can use either separate control system for each skid or one control system for several skids.

- The system is based on SCADA controller, constructed in conformance with industrial automation standards.

- Simple and intuitive user interface provides quick access to all controllers and data.

- Automation of the entire cultivation procedure using pre-programmed ‘sequences’ – for better control of your bioprocess.

- Four-level password control is included, to allow for administrator, manager, supervisor and user level authorization.

You may get detailed information about the main functions of the software:

- Security access

- Controller loops management

- Calibration

- Calculation Module

- Sequences

- Audit Trail

- Profiles

- Graphic Trends

Real stories of SCADA application:

- Process vessels with SIP/CIP

- Flexible industrial biotech system

- Industrial cell culture system