C-BIO2 SCADA system

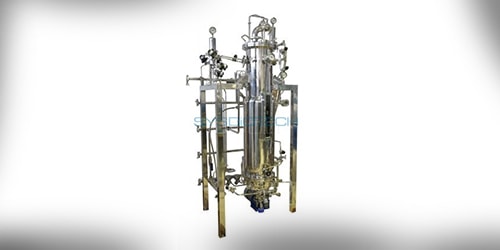

Sysbiotech pilot scale Gas-Fermenter was specially designed for the process of microorganisms cultivation in strictly anaerobic or facultative anaerobic conditions. In this process gas have to be carefully supply and control during cultivating.

System has mass flow controllers on all inlet lines to optimize gas supply with accordance to metabolic needs of microorganism.

Exhaust gas-line equipped with on-line gas analyzers for continues monitoring of gas-contents in exhaust gas-mixture.

On-line sensors allow to monitor and control pH, DO, temperature, ORP, Optical density. Other sensors can be add by request.

To achieve the best mixing conditions we offer different kinds of agitators like Rushton, marine or screw impellers, which can be use separately or in combination with each other.

H/D ration up to 7 was specially developed to achive better conditions for dissolving of inlet gases into media.

System can be designed for Explosion-proof conditions.

Controller system allows to manage and optimize cultivating conditions for CO, CO2, CH4 and another gases of fermentation process.

| Total volume | 10L/50L |

| Working volume | 7L/35L |

| Materials | AISI 316L for wetted parts AISI 304L for non-wetted parts |

| Design pressure | 3.0 kg/cm3 (vessel) 4.0 kg/cm3 (jacket) |

| Design temperature | 1143°С (vessel) 151°С (jacket) |

| Surface finish | Internal polishing Ra 0.8 μm External polishing Ra 1.2 μm |

| Top lid |

Diaphragm Pressure Gauge Diaphragm Pressure Transmitter Rupture disk with outlet pipe Gases exhaust with condensor Inoculation Light glass Foam control with peristaltic pump CIP spray ball | |

| Upper side walls | Air inlet Viewing glass Addition inlet Sparger (ring or micro sparger) | |

| Lower side walls | Temperature sensor PT100

pH control with peristaltic pumps pO2 sensor Sterile sampling system Different sensors available on request: optical density, ORP, level, weight, conductivity, pCO2 | |

| Jacket | Steam inlet / Cooled water outlet Steam outlet / Cooled water supply (with safety valve and manometer) | |

| Bottom | Sterializable bottom valve | |

| Agitation unit | Single mechanical or magnetic seal Manual/automatic speed control depending on the amount of dissolved oxygen. Speed range 30-600 RPM. Up to 1.500 RPM available on request Marine, Rushton or pitched-blade impeller. Different impeller types available on request 3 welded baffles | |

| Aeration unit | Automatic air supply 2 VVM 5" absolute filter 0.2 μm and filter housing made from AISI 316L stainless steel Manual flow meter or automatic MFC (mass flow controller) | |

| Piping | Material | Sanitary grade steel |

| Piping construction | Air supply Plant steam supply Pure steam supply Cooling water supply Cooling water return Waste water drain Waste liquid drain Waste gas out |

|

| Fittings | Diaphragm valve Angle seat valve Steam trap Diaphragm pressure gauge Ball valve and Pneumatic angle valve Check valve Safety valve | |

| Pipes welding | Orbital welding (product line) Manual welding (general line) | |

- Ready-to-work customized solutions with the ability to upgrade

- Fully automatic control

- 100% aseptic design, easy validation

- Different types of impellers: Rushton, marine-blade, pitched-blade right- and left-handed orientation with radial or axial flow

- Drive with magnetic seal.

- Mixing speed 30-600 RPM in standard execution, up to 1.500 RPM on request.

- Standard sensors: temperature, pH, pO2, pressure and foam.

- Sensors on request: optical density, ORP, level, weight, conductivity, pCO2, gas analyzers.

- The purity of gas mixture in bioreactor is guaranteed by 5" absolute filters 0,2 μm

- Gas mixture supply control via automatic MFC (mass flow controller)

- Different sparger types: ring or micro spargers. Different specific designs are available on request.

- Explosion proof configuration

- Special types of gaskets and sealing for strictly anaerobic fermentation.

- Adaptation for different gas mixture.

- Standard Ingold ports for electrodes.