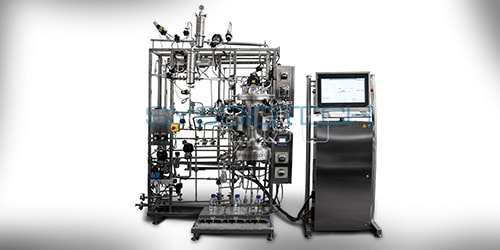

Compact CIP/SIP Fermenters 15L-50L-100L

SYSBIOTECH Pilot-scale Fermenter is a reliable solution for working with microbial process for scientific research, small biotech production facilities as well as for scaling-up.

Standard «ready to use» solutions include all components needed for convenient operation with microbial cultures. After connecting the Fermenter you can start using it right away without having to buy any accessories.

SYSBIOTECH Pilot-scale Fermenters have fully aseptic design and can be validated easily. C-BIO2 control system, universal for any volume of Fermenter greatly simplifies scale-up process and allows for easy transfer of fermentation data.

For your convenience, all the necessary piping is installed on open stainless steel mobile frame. This helps to save space in your facility and simplifies access for maintenance of the Fermenter.

All wetted surfaces are made of AISI 316L stainless steel with surface finish of 0.6 μm, to allow for effective CIP (cleaning-in-place).

Automated and user-configurable CIP and SIP (cleaning-in-place and sterilization-in-place) processing is standard included. A user-friendly program tool allows you to create your CIP and/or SIP sequence by defining its steps and set parameters. By combining sequences you can build a fully automated procedure for your entire application, maximizing day to day process consistency and ensuring best results.

| Vessel (Height : Diameter = 2:1 or 3:1) | |

|---|---|

| Materials | AISI 316L for wetted parts ASISI 304L for non-wetted parts |

|

Design pressure 3.0 kg/cm3 (vessel) 4.0 kg/cm3 (jacket) | |

| Design temperature | 143°С (vessel) 151°С (jacket) |

| Surface finish | Internal polishing 0.4 μm (electropolished) External polishing 1.2 μm |

| Components | |

| Top lid | Diaphragm Pressure Gauge Diaphragm Pressure Transmitter Rupture Disk Gases exhaust with condensor Agitation system (if upper agitation is chosen) Inoculation port Level sensor Foam sensor CIP Spray Ball Sight glass+light |

| Upper side walls | Gases supply Viewing glass Additional feedings Sparger (ring or micro sparger) |

| Lower side walls | Temperature sensor pH sensor pO2 sensor OD sensor Sampling port Spare ports |

| Jacket | Temperature control system Vessel insulation jacket |

| Bottom | Common drain and biowaste drain via sterilizable bottom valve (self-drainable) Agitation system (if bottom agitation is chosen) |

| Agitation unit | |

|

Single/double mechanical or magnetic seal Manual/automatic speed control depending on the amount of dissolved oxygen Speed range 10–800 rpm. Up to 1,500 rpm available upon request Marine, Rushton or pitched-blade impeller. Different impeller types available upon request 3-4 welded or removable baffles Automatic air supply up to 2 vvm PTFE absolute filter 0.2 μm and filter housing made from AISI 316L stainless steel Manual flow meter or automatic MFC | |

| Piping | |

| Material | Sanitary grade steel |

| Piping construction | Air supply Plant steam supply Pure steam supply Cooling water supply Cooling water return Common drain Biowaste drain Exhaust out |

| Fittings | Diaphragm valve Angle seat valve Steam trap Diaphragm pressure gauge Ball valve Check valve Safety valve |

| Pipes welding | Orbital welding (product line) Manual welding (general line) |

- Ready-to-work standard solutions with the ability to upgrade.

- 100% aseptic design, easy validation.

- Different types of impellers: Rushton, marine-blade, pitched-blade right- and left-handed orientation with radial or axial flow.

- Motor with single mechanical or magnetic seal guarantees 100% aseptic operation.

- Mixing speed 30–600 rpm (standard option); up to 1.500 rpm upon request.

- Standard sensors: temperature, pH, pO2, and foam.

- Sensors upon request: OD, ORP, level, weight, conductivity, pCO2, gas analyzers.

- 5" absolute filters 0.2 μm to ensure purity of gas mixture inside the vessel.

- Manual flow meter or automatic mass flow controller (MFC) to regulate supply of gas mixture.

- Different sparger types including ring- or micro-spargers. Various specific designs are available upon request.

- Two in-gold ports for housing any required electrodes.

C-BIO2TM control system features:

- Universal control system for SYSBIOTECH’s fermenters, independent of volume.

- You can use either separate control system for each culture vessel, or one control system for several vessels (parallel experiments, individual vessel control).

- The system is based on SCADA controller, constructed in conformance with industrial automation standards.

- Simple and intuitive user interface provides quick access to all controllers and data.

- Automation of the entire cultivation procedure using pre-programmed ‘sequences’ –for better control of your bioprocess.

- The SCADA software ensures easy and reliable data management and control across all platforms.

- Four level password control is included, to allow for administrator, manager, supervisor and user level authorization.